Cold Rolling Mills

Price 1000000.00 INR/ Piece

Cold Rolling Mills Specification

- Type

- Cold Rolling Mill

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Automatic

- Voltage

- 440 Volt (v)

- Warranty

- 1 Years

Cold Rolling Mills Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 3 Months

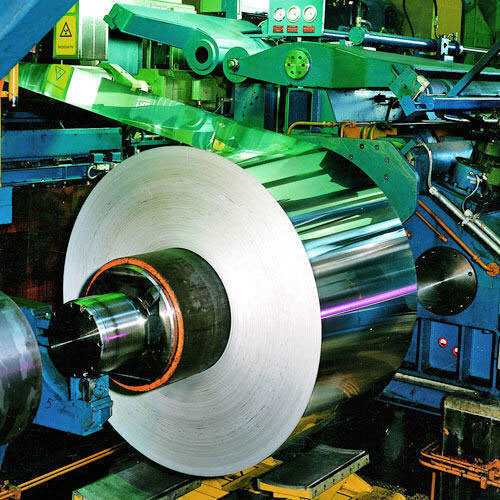

About Cold Rolling Mills

Cold Rolling MillsOur company is noted as one of the well known manufacturers and exporters of Cold Rolling Mills. To manufacture these machines in accordance with the prevailing industry standards, we source tested quality metals from reliable & trusted vendors. These Rolling Mills are easy to install and popular in the market for their sturdy structure and corrosion resistant surface. Cold Rolling Mills is extensively used to roll down aluminum sheet in different thickness. Apart from this, we are offering these machines without any delay.

We design and engineer rolling mills comprise of mill stand, gear boxes, drive systems, coil loading device with uncoilers, coilers, entry & exit tables, measuring and control devices, coil removal system, coolant supply systems, centralized lubrication systems, hydraulic system and complete electrical equipment. The mills are custom designed depending on the material being rolled, thickness and width requirements, production capacity, mode of operation (reversing or non-reversing) and other inputs.

Cold Rolling Mills are perfect for pressing the alloy steel, and making it into sheets, strips and coils form. These machines are engineered with latest technological standards in order to accomplish improved formability, precise dimensions, roughness, and weld-ability for the materials during the process of making. We understand their use in enamelware and galvanizing industry, and as base material for the production of tin-mill-black-plate food cans in food & beverage sector. In order to offer our clients with the best quality formative surfaces we utilize a facility of batch annealing furnace along with pure hydrogen condition.

We bring forth superior nature of Cold Rolling Mills for Stainless Steel, which yields excellent power as well as resilience to the stainless steel products. These mills help in improving the tensile strength and surface finish of the stainless steel sheets, coils and strips. We offer Cold Rolling Mills for Mild Steel also, which is used especially for manufacturing soft steel applicable in domestic goods, cars, constructional steel, wire, plate, tin cans, etc. The company offers a complete range of Cold & hot Rolling Mills for Alloys & Metals utilized in the production of various metal forms such as steel, copper, aluminium, brass strip, and more. The machines helps use produce a superlative range of industrial copper & brass products.

Cold Rolling Mills Key Attributes:

- Sturdy Built For Accurate Performance

- Better Strip Thickness Accuracy, Improved Production Capacity

- Increased Strip Surface Quality, Decrease In Strip / Coil Damages

- Reduction In Operating Cost, Flexible Grip Recoiler

- Tight Tolerance For Strip Thickness & Flatness

- Anti Corrosive, Comparatively Low Price

- Greater Longevity, Smooth Operation

- Easy to Install and Operate

Exclusive Products Specifications:

- Mill Stand,Drive Systems

- Coil Loading Device With Uncoilers, Coilers

- Measuring And Control Devices

- Coil Removal System

- Coolant Supply Systems

Products Key Features:

- Compact Designs

- Sturdy Construction

- Energy Efficient Models

- Easy Operating System

- High Productivity

Our Quality Promise

Quality of the products assumes central importance for us and we never compromise with that. We follow a stringent quality affirmation program that entails comprehensive testing of the finished products. Not only this, we also closely observe the entire production process right from the procurement of raw materials till the delivery of products to clients. The program is implemented by a team of quality analysts having vast knowledge of the raw materials to be used for the production of Cold Rolling Mills.

Why You Choose Us?

- Our factories are accessible in tweaked plans, according to the determinations gave by the clients. Here are a few components why you pick us:

- Broad involvement in planning and building up all sort of moving factories attributable to the solid foundation of specialized consultancy.

- Superb configuration ability highlighting high operational proficiency and long utilitarian life that gets through the exact mix of hypothetical and viable information including propelled 3D outline programming.

- Utilization of brilliant crude material at perfect time and opportune place, for example, Rolls, Screw Down, and numerous others.

- Solid machining resistance with better warmth treatment arrangements.

- Speedy, simple, and successful support alongside erection and establishment office.

Client Contentment

We are exceptionally delicate to the needs of the clients as our association accepts that the clients merit the best esteem for their cash. This client centered methodology has won us awesome honors both in the residential and universal markets. We work in close coordination with the clients to comprehend their particular necessities and tailor the items like frosty moving plants and so forth as needs be. The administration responsibility to clients has made Vaid Engineering Industries a name to trust for excellent scope of Coil Slitting Line & Cold and Hot Rolling Mills.

Our Infrastructure

Our well-laid business framework joins all the offices for outline advancement, generation, quality testing, stockpiling, and so on. The configuration unit contains hello tech outlining devices and programming emotionally supportive network to draft the format of the frosty moving plants and immediately, add to the models for creation. Our assembling unit is fused with the most developed scope of assembling hardware that enlivens the models made by the creators. All the offices are kept an eye on by experienced experts having inconceivable information of their separate areas.

Product details

|

Country of Origin |

Made in India |

|

Material |

MS |

|

Phase |

Single Phase |

|

Power |

1 kW |

|

Production Capacity |

1-3 ton/day |

|

Rolled Shape |

Wire |

|

Mill Type |

Cold Rolling Mill |

|

Automation Grade |

Automatic |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cold Rolling Mill Category

2Hi Cold Rolling Mill

Price 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 440 Volt (v)

Material : Mild Steel

Type : Cold Rolling Mill

Automatic Grade : Automatic

Copper Brass Cold Rolling Mills

Price 1000000 INR / Container

Minimum Order Quantity : 1 Container

Voltage : 440 Volt (v)

Material : Mild Steel

Type : Cold Rolling Mill

Automatic Grade : SemiAutomatic

Copper Strip 4 Hi Cold Rolling Mill

Price 1000000 INR / Container

Minimum Order Quantity : 1 Container

Voltage : 440 Volt (v)

Material : Mild Steel

Type : Cold Rolling Mill

Automatic Grade : SemiAutomatic

Mild Steel Cold Rolling Mills Machines

Price 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 440 Volt (v)

Material : Mild Steel

Type : Cold Rolling Mill

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese